Aramid is a superfiber

that is resistant to fire,

bullets, and extreme loads!

-

x5 STRONGER

Incredible strength — 5 times stronger than steel at the same weight! -

+500°C

Fire resistance — withstands temperatures up to +500°C without melting. -

Lightweight and flexible

Despite its incredible strength, it remains easy to process. -

Chemical resistance

Does not degrade under the influence of acids, alkalis, and solvents.

Applications

and Industries

Ballistics

Aramid fibers are used in bulletproof vests and protective gear for the military, police, and emergency services —

providing high strength with low weight.

Aviation and Space

Aramid is used in the fuselage and protective elements of aircraft — making structures lighter and stronger, enhancing

safety and efficiency.

Marine Operations

Aramid ropes, cables, and pipelines are resistant to moisture, oils, and chemicals — they are reliable and withstand

extreme conditions.

Automotive Industry

Our aramid materials are used in the production of reinforced tires and brake pads — combining strength, durability, and

lightweight properties.

Telecommunications

Aramid is the ideal material for reinforcing fiber optic cables: it enhances their strength, flexibility, and resistance

to mechanical stress.

Workwear and Fire-Resistant Materials

We create materials that provide protection from fire, high temperatures, and chemicals — for workers, firefighters, and

rescuers in high-risk environments.

High Strength — Step by Step

Manufacturing Stages

Polymer Synthesis

PPD and TPC form a liquid polymer in a solution (NMP).

Fiber Formation

The polymer is extruded through filters into an acid bath, washed, and neutralized.

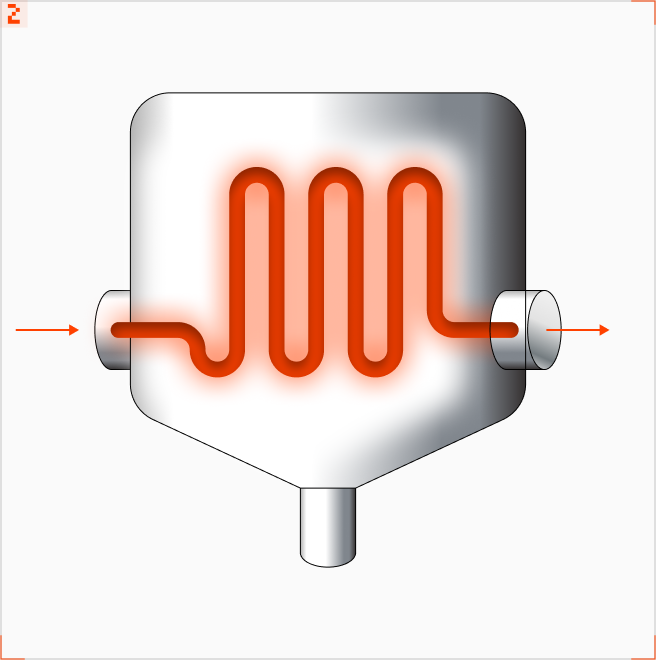

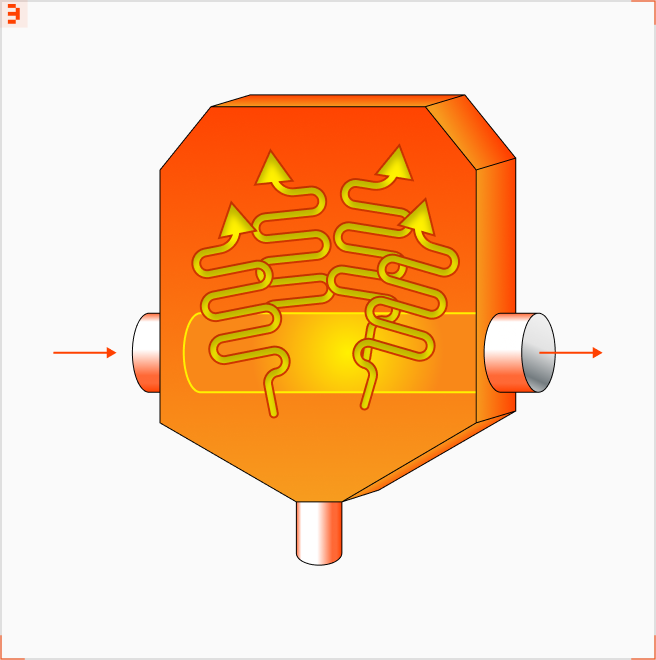

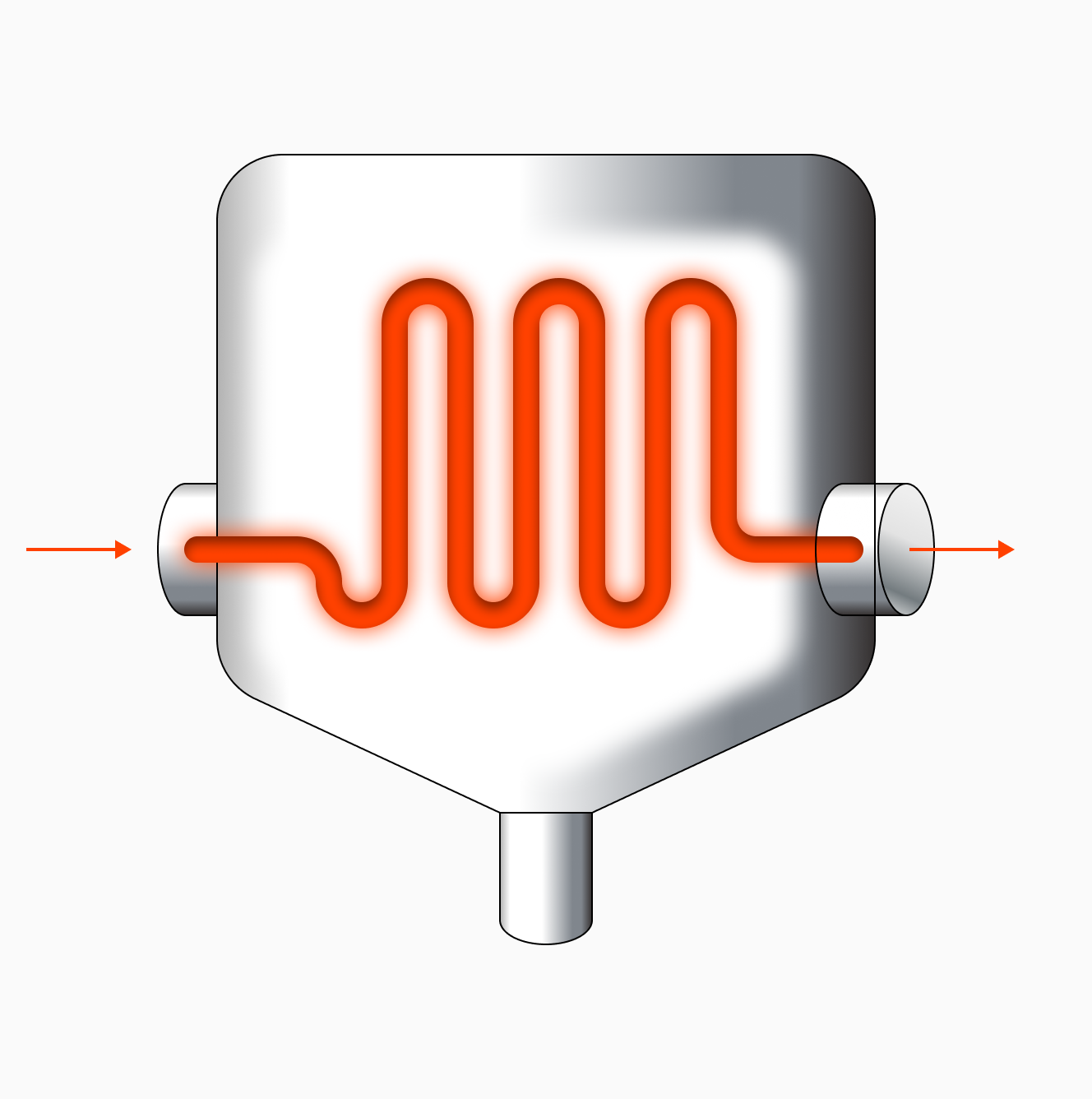

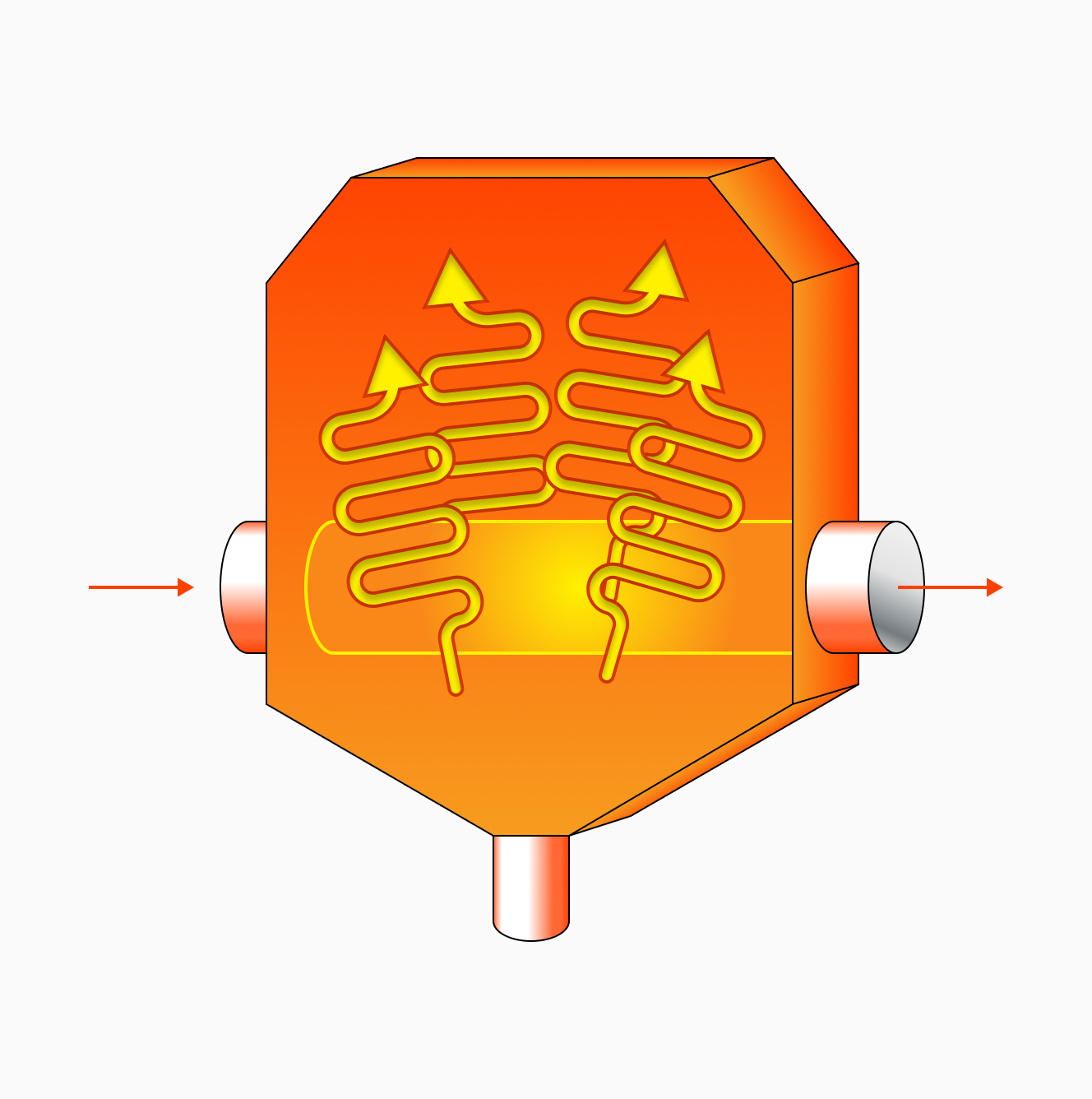

Stretching and Heat Treatment

A temperature of 500-550°C aligns the molecules and increases strength.

Spinning and Twisting

The fibers are twisted into threads and impregnated if necessary, for example, to provide antistatic properties.

Quality Control

Testing for tensile strength, heat resistance, and chemical resistance.